Leading Drying Equipment Manufacturer

As a trusted drying equipment manufacturer, our machines are designed to meet quality standards and your production needs.

Drying Equipment We're Expert

Recent Projects We Have Finished

-

Titanium Dioxide Flash Drying ProjectTitanium Dioxide Flash Drying ProjectDuring the production of titanium dioxide, the materials have a high moisture content and tend to agglomerate. The flash dryer utilizes high-speed dispersion and instantaneous heat transfer to achieve continuous and uniform drying. The equipment can complete dehydration in a short residence time, effectively controlling particle size distribution and meeting the requirements for subsequent powder processing and packaging.

Titanium Dioxide Flash Drying ProjectTitanium Dioxide Flash Drying ProjectDuring the production of titanium dioxide, the materials have a high moisture content and tend to agglomerate. The flash dryer utilizes high-speed dispersion and instantaneous heat transfer to achieve continuous and uniform drying. The equipment can complete dehydration in a short residence time, effectively controlling particle size distribution and meeting the requirements for subsequent powder processing and packaging. -

Plant Extract Spray Drying ProjectPlant Extract Spray Drying ProjectPlant extracts have complex compositions and are highly heat-sensitive. Spray dryers instantly atomize the liquid and rapidly convert it into powder, helping to preserve the active ingredients. The system operates stably, and the resulting powder has good flowability, making it suitable for the industrial production of functional ingredients.

Plant Extract Spray Drying ProjectPlant Extract Spray Drying ProjectPlant extracts have complex compositions and are highly heat-sensitive. Spray dryers instantly atomize the liquid and rapidly convert it into powder, helping to preserve the active ingredients. The system operates stably, and the resulting powder has good flowability, making it suitable for the industrial production of functional ingredients. -

DG Starch Airflow Drying ProjectDG Starch Airflow Drying ProjectDG starch still has a relatively high moisture content after dewatering. The airflow dryer utilizes high-speed hot air to achieve rapid drying and conveying in a single process. The drying process is uniform, and the finished product has stable moisture content, making it suitable for continuous food processing production lines.

DG Starch Airflow Drying ProjectDG Starch Airflow Drying ProjectDG starch still has a relatively high moisture content after dewatering. The airflow dryer utilizes high-speed hot air to achieve rapid drying and conveying in a single process. The drying process is uniform, and the finished product has stable moisture content, making it suitable for continuous food processing production lines. -

Iron Phosphate Drying and CalcinationIron Phosphate Drying and CalcinationIron phosphate materials require strict control over moisture and heat treatment processes. The drying and calcination equipment provides stable temperature control and continuous operation. This system helps improve material reaction consistency and provides reliable pre-treatment conditions for the subsequent preparation of new energy battery materials.

Iron Phosphate Drying and CalcinationIron Phosphate Drying and CalcinationIron phosphate materials require strict control over moisture and heat treatment processes. The drying and calcination equipment provides stable temperature control and continuous operation. This system helps improve material reaction consistency and provides reliable pre-treatment conditions for the subsequent preparation of new energy battery materials. -

Chinese Medicine Extract Spray DryingChinese Medicine Extract Spray DryingTraditional Chinese medicine extracts have high viscosity and tend to stick to the walls of the drying chamber. The ZLPG series spray dryer is designed with optimized structure and airflow to address these characteristics. It offers high drying efficiency, producing uniform powder that facilitates subsequent pharmaceutical production and quality control.

Chinese Medicine Extract Spray DryingChinese Medicine Extract Spray DryingTraditional Chinese medicine extracts have high viscosity and tend to stick to the walls of the drying chamber. The ZLPG series spray dryer is designed with optimized structure and airflow to address these characteristics. It offers high drying efficiency, producing uniform powder that facilitates subsequent pharmaceutical production and quality control.

Food Drying

Food Drying Chemical Drying

Chemical Drying Battery Drying

Battery Drying Fetilizer Drying

Fetilizer Drying Sludge Drying

Sludge Drying Mineral Drying

Mineral Drying Plastic Drying

Plastic Drying Catalyst Drying

Catalyst Drying Pharmaceutical Drying

Pharmaceutical Drying Wood Chip Drying

Wood Chip Drying

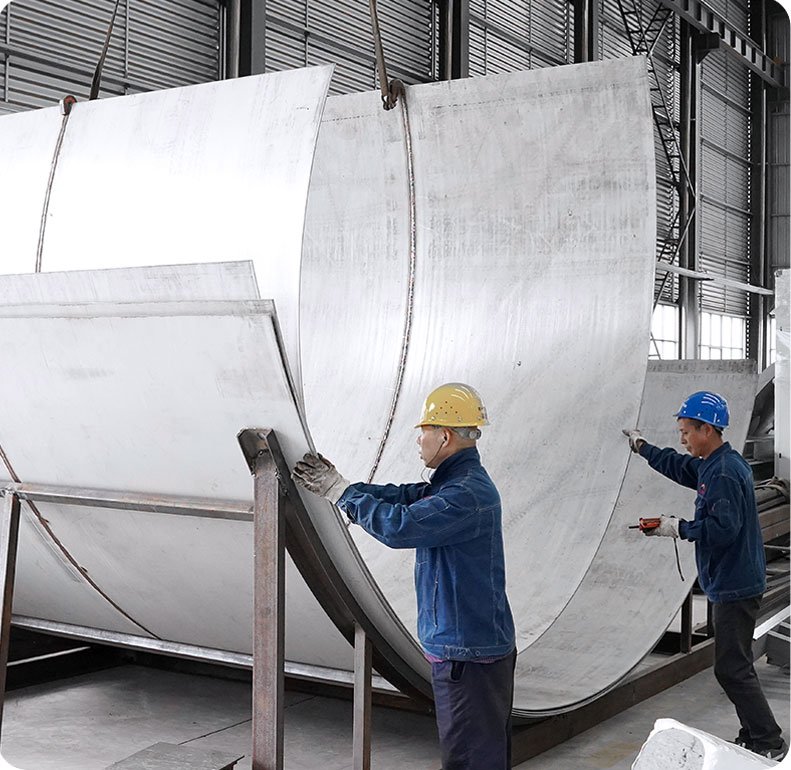

Drying Equipment Manufacturer Leader Since 1993

With decades of experience, we are a trusted drying equipment manufacturer serving customers worldwide. Since 1993, our machines are built to last and designed to meet your production needs.

Designed to Match Your Material and Capacity

Our engineers study your raw material, moisture content, and output requirements. Then we create a drying machine that fits your exact process. This ensures better efficiency, lower energy use, and higher product quality. Each machine is designed to reduce energy consumption while maintaining strong drying performance. Simple controls and user-friendly operation help your team run the system smoothly with minimal training. We also offer technical guidance to help you get the best results.

Check How Our Client Say About FANQUN Drying Machines

We have been using FANQUN drying machines for over a year now. The performance has been very stable. The drying quality is consistent and the energy consumption is lower than our previous system. We will surely purchase again!

We have been using FANQUN drying machines for over a year now. The performance has been very stable. The drying quality is consistent and the energy consumption is lower than our previous system. We will surely purchase again! Adrian HarmonChemical Production Manager

Adrian HarmonChemical Production Manager The installation process was well-organized. The drying system reached full production quickly. FANQUN provided clear training for our operators which made daily operations very easy. Their after-sales support is also fast and reliable. Thank you, FANQUN.

The installation process was well-organized. The drying system reached full production quickly. FANQUN provided clear training for our operators which made daily operations very easy. Their after-sales support is also fast and reliable. Thank you, FANQUN. Carlos RodriguezIndustrial Material Plant Manager

Carlos RodriguezIndustrial Material Plant Manager The build quality of FANQUN drying machines is excellent. The system operates continuously with minimal maintenance. This has helped us reduce downtime and improve plant reliability. We highly recommend FANQUN!

The build quality of FANQUN drying machines is excellent. The system operates continuously with minimal maintenance. This has helped us reduce downtime and improve plant reliability. We highly recommend FANQUN! Robert ThompsonMaintenance Supervisor

Robert ThompsonMaintenance Supervisor The equipment fits our process perfectly and is very easy to operate. Our production efficiency has clearly improved. We really appreciate their strong engineering capability. Our team will surely work with FANQUN on future projects!

The equipment fits our process perfectly and is very easy to operate. Our production efficiency has clearly improved. We really appreciate their strong engineering capability. Our team will surely work with FANQUN on future projects! Anna MullerPharmaceutical Project Engineer

Anna MullerPharmaceutical Project Engineer

FAQ

Yes. We design and manufacture custom drying machines based on your material, moisture level, capacity, and production process.

FANQUN drying machines are designed to reduce energy consumption while maintaining strong drying performance. We optimize airflow, heat transfer, and control system to help lower your operating cost.

Delivery time depends on the machine and level of customization. Standard equipment usually takes less time while custom drying systems may require additional engineering and manufacturing time.

Our machines are built for long-term use and easy maintenance. Routine checks, basic cleaning, and scheduled servicing are usually enough to keep the system running efficiently. We also provide maintenance guidance and technical support.

Yes. Our drying machines are designed to integrated smoothly with your existing equipment. We evaluate your current production setup and adjust the system design.